Microsoft Dynamics AX 2012 Manufacturing – Lean Ninja IoT Scenario Part 4-2: Functionality/Make to Order

Continuation from here: http://ax2012manufacturing.blogspot.com/2015/10/microsoft-dynamics-ax-2012_9.html

Section: Creation

We'll begin with replenishment of Near Side Line location (BULK-002) from Warehouse bulk location (BULK-001). First we'll introduce a necessary on-hand in BULK-000 location as presented below

On-hand

Then we can run Kanban pegging event routine to generate necessary kanban

Kanban pegging event

Infolog

Please note that Manufacturing kanban has been generated to replenish Near Side Line location from Warehouse bulk location

Kanban rule

Kanban

At this point we are missing BOM structure for kanban, so we are going to assign BOM version manually to kanban using Assign alternative BOM version function

Assign alternative BOM version - Before

Assign alternative BOM version - After

Now we'll look at kanban pegging tree

Kanban pegging tree

And also we'll take a look at inventory transactions

Inventory transactions

Please remember that we are using Manufacturing kanban for replenishment of Near Side Line location from Warehouse bulk location. And the next step will be to plan the entire pegging tree to plan kanban Process job, generate Kanban picking wave and Warehouse work

Plan entire pegging tree

Kanban pegging tree – Kanban jobs

Please note that Kanban Process job changes its status to Planned now

Inventory transactions

At this point we can also review Kanban wave

Kanban wave

and generated Warehouse work

Work

Please note that wave would not be created and items would be picked if I had on-hand in BULK-001 for Wheel2

Now Warehouse worker will use hand-held device to execute Warehouse work

Login

Menu - Inventory

Menu – Inventory – Kanban picking

Kanban picking

Kanban picking

Kanban picking

Kanban picking

Kanban picking

Kanban picking work is now completed and we can take a look at inventory transactions

Inventory transactions

In a meantime we can also see Process kanban job planned on Schedule board and visible on Kanban board for Process jobs

Kanban board – Schedule board

Kanban board – Schedule board

Kanban board - Process jobs

Kanban board - Process jobs

Kanban board - Process jobs (Details)

Kanban board - Process jobs (Picking list)

Kanban board - Process jobs

At this point we could complete kanban straight from Kanban board for process jobs, but instead of this we'll do kanban put away in WMS

Menu - Inventory

Kanban put away

Kanban put away

Kanban put away

Kanban put away

Now when kanban put away work is completed we can take a look at inventory transactions

Inventory transactions

Also we can observe completed kanban on Kanban board for Process jobs

Kanban board for Process jobs

After we completed Manufacturing kanban we have replenished Near Side Line location (BULK-002) from Warehouse bulk location (BULK-001). We can see how inventory on-hand was updated for Wheel2

On-hand

Before we proceed to the next step I want to also introduce additional on-hand for Body in the point of consumption, Line Side location (BULK-003)

Inventory journal

Next we'll place a new Sales order for AlexMotorcycle2

Sales order

Please note that AlexMotorcycle2 finished product is expected to be in a Finished good location (BULK-004). After we save Sales order the system based on Kanban rules in place will automatically create necessary kanbans. We can review created kanbans by opening Pegging tree form

Pegging tree (Process kanban)

As you can see according to Kanban rules 2 Kanban jobs will have to be completed to produce AlexMotorcycle2, one for Transfer and another one for Process

Kanban (Process)

Pegging tree (Transfer kanban)

Kanban (Transfer)

This is how inventory transactions look like at this point

Inventory transactions (Wheel2)

Inventory transactions (Body2)

Inventory transactions (AlexMotorcycle2)

Now I'll plan the entire pegging tree

Plan pegging tree

Please note that Kanban Process job has been Planned, and no Kanban picking wave was generated

Pegging tree – Kanban jobs

In a meantime we can review Transfer and Process jobs on Kanban board for Transfer jobs and Kanban board for Process jobs correspondingly

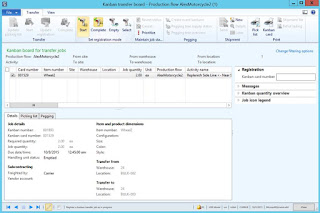

Kanban board for Transfer jobs

Kanban board for Transfer jobs

Kanban board for Transfer jobs - Details

Kanban board for Transfer jobs – Picking list

Kanban board for Transfer jobs - Pegging

Kanban schedule board

Kanban board for Process jobs

Kanban board for Process jobs

Kanban board for Process jobs - Details

Kanban board for Process jobs – Picking list

Kanban board for Process jobs - Pegging

You can also review Process job and Transfer job on the same screen as presented below

Kanban board for Process jobs

Now we can begin the execution of kanbans

Section: Execution

We'll begin with Starting Transfer job first

Transfer – Start

In case you want to do partial picking you can use Pick screen as presented below

Pick

Here's how inventory transactions look like after this step

Inventory transactions

Then we'll complete Transfer

Transfer – Complete

In case you want to do partial registration you can use Registration screen as presented below

Registration

Here's how inventory transactions look like after this step

Inventory transactions

As we complete Transfer now we have enough Wheels in its Part location for Workcell worker to execute Assembly process. We'll start Process kanban job now

Process job - Start

In case you want to do partial picking you can use Pick screen as presented below

Pick

Pick

Please note that according to Storage dimension group I had to specify Locations on both lines

And again we'll take a look at inventory transactions

Inventory transactions (Wheel2)

Inventory transactions (Body2)

In case we need to complete partial quantity or specify Good/Error quantities you can use Complete job and error details screen as presented below

Process job – Complete with details

Process job

In case you need to update partial registration you can use Registration screen as presented below

Registration

Now we can take a look at inventory transactions again

Inventory transactions (AlexMotorcycle2)

Inventory transactions (Wheel2)

Inventory transactions (Body2)

Once we completed Manufacturing kanban we can see finished product is available in Finished goods location now

On-hand

And because we have produced the product we can now send it to the customer

Sales order – Packing slip and Invoice

Please note Location is specified on Sales order line per Storage dimension group requirement

After we updated Sales order physically and financially we can review inventory transactions

Inventory transactions (AlexMotorcycle2)

Inventory transactions (Body2)

Inventory transactions (Wheel2)

The very last step will be to run Lean costing routine to cost the production flow

Section: Costing

Cost the production flow

Prompt

Please note that no further registrations of kanban jobs will be possible after the date costing, but that's fine for the sake of this demo

Inventory transactions (AlexMotorcycle2)

Inventory transactions (Body2)

Inventory transactions (Wheel2)

To be continued here: http://ax2012manufacturing.blogspot.com/2015/10/microsoft-dynamics-ax-2012_70.html

Tags: Microsoft Dynamics AX 2012 R3, Lean Manufacturing, Pull, Kanbans, Kanban rules, Production flow, Warehouse Management, Hand-held devices.

Note: This document is intended for information purposes only, presented as it is with no warranties from the author. This document may be updated with more content to better outline the issues and describe the solutions.

Author: Alex Anikiev, PhD, MCP

Special thanks for collaboration in building this scenario goes to Lean Transformation Guru at MCAConnect, Phil Coy

"• Nice and good article. It is very useful for me to learn and understand easily. Thanks for sharing your valuable information and time. Please keep updating IOT Online Training

ReplyDelete"

I want to share a testimony on how Le_Meridian funding service helped me with loan of 2,000,000.00 USD to finance my marijuana farm project , I'm very grateful and i promised to share this legit funding company to anyone looking for way to expand his or her business project.the company is funding company. Anyone seeking for finance support should contact them on lfdsloans@outlook.com Or lfdsloans@lemeridianfds.com Mr Benjamin is also on whatsapp 1-989-394-3740 to make things easy for any applicant.

ReplyDelete