Microsoft Dynamics AX 2012

Manufacturing – Process Primer

Purpose: The purpose of this document is to illustrate process manufacturing approach in Microsoft Dynamics AX 2012 on simplified example of Car tires manufacturing. This document will outline end-to-end functional flow for the scenario which includes setup (Section A), creation (Section B), estimation (Section C), scheduling (Section D), execution (Section E) and costing (Section F) aspects. Please review other documents in the series to compare traditional manufacturing approach to other manufacturing approaches in Microsoft Dynamics AX 2012.

Challenge: Microsoft Dynamics AX 2012 out-of-the-box enables mixed mode manufacturing including traditional approach and process approach. Process manufacturing in Microsoft Dynamics AX 2012 has introduced number of new concepts such as formulas, co-products, by-products, etc. The idea is that the reader with understanding of traditional manufacturing approach will be able to adopt this knowledge in order to implement process manufacturing scenarios in Microsoft Dynamics AX 2012.

Solution: The simple but at the same time descriptive real-world example of Car tires manufacturing provides context for better understanding of manufacturing processes and their implementation in Microsoft Dynamics AX. In particular we will be dealing with single level formula, co-product and by-product, as well as straightforward sequential route in order to implement Make to Stock scenario. Make to Stock scenario was implemented for the sake of simplicity, however we can also apply this knowledge to implement Make to Order scenario if needed.

Scenario

In this scenario Car tire will be manufactured using process approach. Car tire ingredients will be put together in order to manufacture finished product. One team will be responsible for Car tire manufacturing.

Formula

|

Route

|

One of the important requirements defined in this scenario is that all products are Standard cost controlled

Section A: Setup

Let's review the setup which is required to implement this scenario

Number of released products will be created in Microsoft Dynamics AX 2012 which will have similar characteristics for the sake of simplicity. All of them will be Standard cost controlled, Site and Warehouse will be used as Storage dimensions, default Site and Warehouse settings will be defined for released products and finally cost price will also be defined for all released products (not using Formula calculation for Formulas). Please note that in process industries we deal with Batch controlled products however for the sake of simplicity I didn't introduce Batch as Tracking dimension in this scenario.

For Car tire (AlexTire) manufacturing we will need the following ingredients: Rubber, Carbon and Zink oxide. Please note that as the result of Car tire (AlexTire) manufacturing we will also have Co-Slag co-product and By-Slag by-product.

Released product: Tire (AlexTire)

Car tire (AlexTire) released product will be created using decentralized approach

Cost price for Car tire (AlexTire) is 75$

Site "1" will be used as default Site for Purchase, Inventory and Sales

Within Site "1" Warehouse "11" will be used as default Warehouse for Purchase, Inventory and Sales

Car tire (AlexTire) will be manufactured that's why Production type = "Formula"

Released product: Rubber

Rubber released product will be created using decentralized approach

Cost price for Rubber is 3$/Lbs

Site "1" will be used as default Site for Purchase, Inventory and Sales

Within Site "1" Warehouse "11" will be used as default Warehouse for Purchase, Inventory and Sales

Released product: Carbon

Carbon released product will be created using decentralized approach

Cost price for Carbon is 4$/Lbs

Site "1" will be used as default Site for Purchase, Inventory and Sales

Within Site "1" Warehouse "11" will be used as default Warehouse for Purchase, Inventory and Sales

Released product: Zink oxide

Zink oxide released product will be created using decentralized approach

Cost price for Zink oxide is 50$/Lbs

Site "1" will be used as default Site for Purchase, Inventory and Sales

Within Site "1" Warehouse "11" will be used as default Warehouse for Purchase, Inventory and Sales

Released product: Co-Slag

Co-Slag released product will be created using decentralized approach

Cost price for Co-Slag is 1$/Lbs

Site "1" will be used as default Site for Purchase, Inventory and Sales

Within Site "1" Warehouse "11" will be used as default Warehouse for Purchase, Inventory and Sales

Released product: By-Slag

By-Slag released product will be created using decentralized approach

Cost price for By-Slag is 2$/Lbs

Site "1" will be used as default Site for Purchase, Inventory and Sales

Within Site "1" Warehouse "11" will be used as default Warehouse for Purchase, Inventory and Sales

Released products

When all released products are created you can see them on Released products list page

Please note that Car tire (AlexTire) has Production type = Formula, Co-Slag has Production type = Co-product and By-Slag has Production type = By-product

Car tire (AlexTire) will be manufactured using 3 operations routes. Before we can define routing we will need to define the list of operations in the system

Operations

Car tire (AlexTire) will be manufactured by one team

Resource group: AlexTire

Car tire (AlexTire) will be manufactured by Alex Tire Team 1

Resource: AlexTire1

Alex Tire Team 1 will consists of 1 worker: Arnie Mondloch

Please note that Alex tire Team 1 will be responsible for Car tire (AlexTire) manufacturing

From costing perspective the cost prices for different types of labor will be defined through Cost categories

Cost category: Setup

Cost price for Setup labor will be 18$

Cost category: Run time

Cost price for Process labor will be 15$

Cost category: Quantity

Cost price per Quantity manufactured will be 2$

Costing sheet

The structure of manufacturing costs will be defined in Costing sheet

Please note that Costing sheet is also used to define and calculate different types of overheads such as material overhead, labor overhead and plant overhead

Car tire (AlexTire) formula will consist of Rubber, Carbon and Zink oxide ingredients. Please note that the formula also defines Co-Slag co-product and By-Slag by-product as secondary outcomes from production process

Formula: AlexTire – Designer view

Designer view provides a visual representation of Car tire (AlexTire) formula

Please note that Co-Slag co-product and By-Slag by-product are listed under Co-products in Designer view

Formula: AlexTire – Lines view

Designer view provides a grid representation of Car tire (AlexTire) formula

Formula: AlexTire – Co-Products

You can define secondary outcomes from production process such as co-products and by-products on Co-products screen. In the case of Car tire (AlexTire) formula they are Co-Slag co-product and By-Slag by-product

Car tire (AlexTire) route will consist of Mixing, Building and Curing operations which will be executed sequentially

Route: AlexTire

Please note that different Cost categories are specified for Setup, Run time and Quantity for all route operations

Please note that Curing operation requires Queue time before (0.25 hours) and Queue time after (0.25 hours) as well as Run time (1 hour)

Please note that Resource requirements are specified for all route operations

Section B: Creation

In Make to Stock scenario we will create Batch order for Car tire (AlexTire) manually

Batch order: AlexTire

Batch order is a document which in process scenario controls manufacturing process of certain quantity of goods within defined timeframe

Production orders

When batch order is created you can see it on Production orders list page

When batch order is created the system will copy product’s active Formula and active route in order to create production Formula and production route

Batch order: AlexTire – Production Formula

Production Formula is a list of ingredients to be used for this particular Batch order

Please note that you can change Batch Formula to meet specific requirements for particular Batch order without affecting product’s active Formula

Batch order: AlexTire – Production Co/By-products

Production Co/By-products represent secondary outcomes from production process

Please note that you can change Batch Co/By products to meet specific requirements for particular Batch order without affecting product’s standard Co/By products defined on the formula if you allow for Co-products variations

Batch order: AlexTire – Production cost

You can also define a cost distribution between your formula and co-products as well as burden related to disposal of by-products

Batch order: AlexTire – Production Route

Production Route is a list of operations to be used for this particular Batch order

Please note that you can change Batch Route to meet specific requirements for particular Batch order without affecting product’s active Route

At this moment we only have 1 inventory transaction representing batch order receipt for Car tire (AlexTire)

Inventory transactions

Section C: Estimation

The next step in Car tire (AlexTire) batch order life cycle is to estimate batch order

Batch order: AlexTire – Estimate

It’s important to mention that during estimation the system will create inventory issue transactions for Formula ingredients, create inventory receipt transactions for Co/By products, calculate estimated cost of manufactured product and create related Batch orders for manufactured sub-ingredients if needed

Once estimation is finished you can see the list of batch orders on Production orders list page

Production orders

From costing perspective after estimation the system calculated estimated cost of batch order based on production Formula and production route

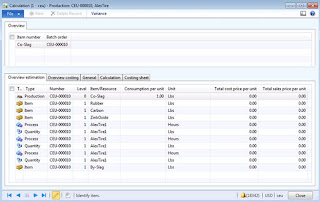

Batch order: AlexTire – Price calculation

Please note that the system segregates consumption of materials from consumption of labor on Overview estimation tab. Also different types of overhead costs were added based on Costing sheet setup

However on Costing sheet tab you can also see an aggregated Total as well as breakdown based on Cost groups defined in Costing sheet

You can also review Price calculation details for co-products

In this particular example no cost will be allocated to co-product. Please see Appendix A for different examples of cost allocation

After estimation the system created all necessary issue inventory transactions for Formula components for Car tire (AlexTire) and receipt inventory transactions for Co/By products

Inventory transactions

Section D: Scheduling

The next step in Car tire (AlexTire) batch order life cycle is to schedule batch order

In this particular scenario I’ll execute Job scheduling which will generate number of jobs and provide exact dates and times for them

Batch order: AlexTire – Job Scheduling

Production orders

Once Job scheduling is finished you can see the list of batch orders and their statuses on Production orders list page

Please note that the system scheduled batch order and generated number of jobs based on times defined on route operations

Batch order: AlexTire – Jobs

As the result of Job scheduling based on Batch Route the system generated a number of jobs

Batch order: AlexTire – Gantt chart

Gantt chart provides visual representation of production schedule, ability to reschedule for the user by dragging and dropping bars and much more

Please note that Gantt chart provides 2 views: Order view and Resource view

At this moment no changes happened to inventory transactions, however by the result of scheduling the system did appropriate capacity reservation for resources involved

Inventory transactions

Section E: Execution

The next step in Car tire (AlexTire) batch order life cycle is to release batch order which releases batch order from top floor to shop floor and indicates that batch order can be started

Batch order: AlexTire – Release

Production orders

Once release is finished you can see the list of batch orders and their statuses on Production orders list page

At this moment no changes happened to inventory transactions

Inventory transactions

The next step in Car tire (AlexTire) batch order life cycle is to start batch order

Batch order: AlexTire – Start

In this case I’ll pre-flush materials and labor consumption which means that material and labor consumption will be posted up-front. Please notice “Post picking list now” and “Post route card now” checkboxes which are marked. I assume that there’s enough on-hand for the ingredients to be consumed

Please note that you can also back-flush materials and labor consumption which means that material and labor consumption may be posted at the time when you report your batch order as finished

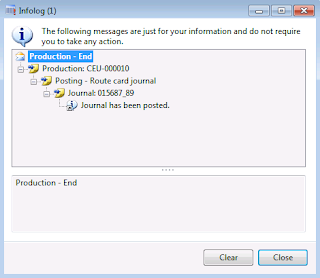

Infolog

As the result the following message will be displayed informing that Picking list journal and Route card journal have been posted for the consumption of material and labor

Production orders

Picking list journal is used to post material consumption

Batch order: AlexTire – Picking list journal

Picking list journal header references Batch order for Car tire (AlexTire)

Picking list journal lines have details of what ingredients have been picked for Car tire (AlexTire) production

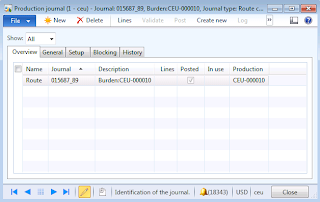

Route card journal is used to post labor consumption

Batch order: AlexTire – Route card journal

Route card journal header references Batch order for Car tire (AlexTire)

Route card journal lines have details of what operations have been performed for Car tire (AlexTire) production

Batch order: AlexTire – Jobs

Please note that Job status for jobs changed to Waiting

At this moment the system physically updated issue inventory transactions for Car tire (AlexTire) Formula ingredients. By other words ingredients for Car tire (AlexTire) have been used in production process

Inventory transactions

Please note that issue inventory transactions for Car tire (AlexTire) Formula ingredients changed their statuses to Deducted

Batch order: AlexTire – Production posting

The result of material and labor consumption for Car tire (AlexTire) batch order is reflected in Production posting details

Please note that the system also calculated Indirect costs based on Costing sheet setup

Please see details of Production posting for Car tire (AlexTire) batch order in the table below

Material consumption

Material consumption is 39$ based on cost of Car tire (AlexTire) Formula ingredients

*Inventory transactions

Inventory issue transactions for Car tire (AlexTire) Formula ingredients will be displayed on Voucher transactions screen for material consumption

*Voucher transactions

Ledger voucher provides details on which account was credited for “Production, picking list”, which account was debited for “Production offset picking list” as well as on additional postings happened because of material overhead applied

Route consumption

Route consumption is 43.5$ based on cost of operations for Process and per Quantity for Car tire (AlexTire)

*Inventory transactions

Inventory receipt transaction for Car tire (AlexTire) will be displayed on Voucher transactions screen for route consumption

*Voucher transactions

Ledger voucher provides details on which account was credited for “Production WIP issue”, which account was debited for “Production - WIP” as well as on additional postings happened because of labor overhead applied

*Route transactions

Route transactions show the details of labor consumption postings for Process jobs (37.50$) and per Quantity (6$) which rolls up to 43.50$

Indirect cost

Indirect cost 5.23$ represents labor overhead applied to labor consumption based on Costing sheet setup. Please note that plant overhead is calculated based on labor overhead and contributes to the sum

*Inventory transactions

Inventory receipt transactions for Car tire (AlexTire) will be displayed on Voucher transactions screen for indirect cost

*Voucher transactions

Ledger voucher provides details on which account was credited for “Estimated indirect absorption”, which account was debited for “Estimated indirect absorption offset” in regards with labor overhead applied

*Indirect cost transactions

Indirect cost transactions provide information regarding the breakdown of indirect costs incurred which are related to labor consumption according to cost groups set up in Costing sheet

Indirect cost

Indirect cost 0.79$ represents material overhead applied to material consumption based on Costing sheet setup. Please note that plant overhead is calculated based on material overhead and contributes to the sum

*Inventory transactions

Inventory receipt transactions for Car tire (AlexTire) will be displayed on Voucher transactions screen for indirect cost

*Voucher transactions

Ledger voucher provides details on which account was credited for “Estimated indirect absorption”, which account was debited for “Estimated indirect absorption offset” in regards with material overhead applied

*Indirect cost transactions

Indirect cost transactions provide information regarding the breakdown of indirect costs incurred which are related to material consumption according to cost groups set up in Costing sheet

|

The next step in Car tire (AlexTire) batch order life cycle is to report production order as finished

Batch order: AlexTire – Report as finished

Formula - General

Co-product – Overview

By-product - General

Please note that “End job” checkbox is marked which means that while reporting batch order as finished I intend to mark all batch order jobs as completed

Infolog

As the result the following message will be displayed informing that Report as finished journal has been posted for the receipt of finished goods as well as co/by products into inventory

Once you reported batch order as finished you can see the list of Production orders on Production orders list page

Production orders

Report as finished journal is used to record finished good receipt as well as co/by product receipts into inventory

Batch order: AlexTire – Report as finished journal

Report as finished journal header references Batch order for Car tire (AlexTire)

Report as finished journal lines have details of what finished goods and what co/by products have been received into inventory

Batch order: AlexTire – Jobs

Please note that Job status for jobs changed to Ended

Inventory transactions

At this moment the system physically updated receipt inventory transaction for Car tire (AlexTire) as well as for Co-Slag co-product and By-Slag by-product. By other words Car tire (AlexTire) has been produced and is available now as well as secondary outcomes - co/by products: Co-Slag co-product and By-Slag by-product

Batch order: AlexTire – Production posting

The result of reporting Car tire (AlexTire) batch order as finished is reflected in Production posting details

Please see details of Production posting for Car tire (AlexTire) batch order in the table below

Report as finished

Report as finished amount is 75$ based on standard cost of Car tire (AlexTire)

*Inventory transactions

Inventory receipt transactions for Car tire (AlexTire) will be displayed on Voucher transactions screen for Report as finished

*Voucher transactions

<Empty voucher>

Please note that 75$ is standard cost of Car tire (AlexTire)

Report as finished (Co-product)

Report as finished amount is 0.10$ based on standard cost of Co-Slag co-product

*Inventory transactions

Inventory receipt transactions for Co-Slag co-product will be displayed on Voucher transactions screen for Report as finished

*Voucher transactions

<Empty voucher>

Please note that 0.10$ is standard cost of Co-Slag co-product

Report as finished (By-product)

Please note that By-Slag by-product will add to the cost of finished goods and co-products and Report as finished amount for By-Slag by-product by itself is 0 (Zero)

*Inventory transactions

Inventory receipt transactions for By-Slag by-product will be displayed on Voucher transactions screen for Report as finished

*Voucher transactions

<Empty voucher>

|

Section F: Costing

The next step in Tire (AlexTire) batch order life cycle is to end batch order

Batch order: AlexTire – End

Once you ended batch order you can see the list of batch orders on Production orders list page

Production orders

From costing perspective after ending batch order the system calculated actual cost of batch order based on actual material and labor consumption

Batch order: AlexTire – Price calculation

Please note that the system segregates consumption of materials from consumption of labor on Overview costing tab. Also different types of overhead costs are represented based on Costing sheet setup

However on Costing sheet tab you can also see an aggregated Total as well as breakdown based on Cost groups defined in Costing sheet

You can review production variances on Production variances screen

You can also review Price calculation details for co-products

You can review production variances for Co-products on Variance screen as Summary

Or you can review production variances for Co-products on Variance screen in Details

In this particular example no cost will be allocated to co-product. Please see Appendix A for different examples of cost allocation

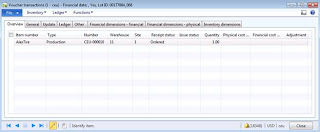

Inventory transactions

At this moment the system financially updated all receipt and issue inventory transactions related to Car tire (AlexTire) production

Please note that the system recorded financial costs for inventory transactions according to posted material and labor consumption as well as all applied overheads, and also it calculated adjustments to predefined standard costs. Adjustments to standard cost were needed because initially I didn’t use Formula calculation to calculate cost price of manufactured products and specified their cost prices manually. Please note that the system didn’t record any financial costs for Co/By products because in this simplified setup the cost of production is not allocated onto Co-Slag Co-product and the cost of By-Slag by-product doesn’t add burden to the cost of production. Please see Appendix A and Appendix B for examples of different setups as it relates to cost allocation for co-products and burden cost for by-products. The system didn’t record any financial costs for Co/By products, however standard cost adjustments were made to Co/By product inventory transactions as usually

Batch order: AlexTire – Production posting

The result of ending Car tire (AlexTire) batch order is reflected in Production posting details

Please see details of Production posting for Car tire (AlexTire) batch order in the table below

Costing

Costing amount 88.50$ reflects the actual cost of batch order which includes material consumption, labor consumption and various overheads applied

*Inventory transactions

All inventory transactions related to Car tire (AlexTire) batch order will be displayed on Voucher transactions screen for costing

*Voucher transactions

Ledger voucher provides details on which account was credited for “Production issue” and which account was debited for “Production offset account issue”. Similarly which account was credited for “Production offset account receipt” and which account was debited for “Production receipt”. Cost adjustment is reflected in “Production substitution variance” posting.

Please note that when batch order was ended the system reversed all previous postings for WIP (Work in process) including material consumption, labor consumption and all applied overheads

Costing (Co-product)

Costing amount 0$ reflects the fact that production cost is not allocated to co-products in this scenario

*Inventory transactions

All inventory transactions related to Car tire (AlexTire) production order will be displayed on Voucher transactions screen for costing

*Voucher transactions

Ledger voucher provides details on which account was credited for “Production issue” and which account was debited for “Production offset account issue”. Similarly which account was credited for “Production offset account receipt” and which account was debited for “Production receipt”. Cost adjustment is reflected in “Production substitution variance” posting.

Please note that when batch order was ended the system reversed all previous postings for WIP (Work in process) including material consumption, labor consumption and all applied overheads

|

Appendix A: Co-products

Please see different scenarios for cost allocation for co-products described below. For the sake of clarity in these scenarios only co-product (and no by-product) is the secondary outcome for production process

Scenarios

<![if !supportLists]>1. <![endif]>Cost allocation = None

In this scenario the system doesn’t do any cost allocation for co-products

Formula: AlexTire – Co-Products

Please note that Cost allocation = None for Co-Slag co-product. This means that the system will not allocate cost onto Co-Slag co-product

Inventory transactions

Please note that financial cost for Co-Slag co-product inventory receipt transaction is 0 (Zero)

<![if !supportLists]>2. <![endif]>Cost allocation = Manual

In this scenario the system will do cost allocation for co-products in accordance with Cost allocation percent specified manually

Formula: AlexTire – Co-Products

Please note that Cost allocation = Manual and Cost allocation percent = 50% for Co-Slag co-product. This means that the system will evenly (50%/50%) allocate cost onto Co-Slag co-product and Car tire (AlexTire) product based on total production cost

Inventory transactions

Please note that financial cost for Co-Slag co-product inventory receipt transaction is 44.25$ which equals to financial cost for Car tire (AlexTire) inventory receipt transaction

<![if !supportLists]>3. <![endif]>Cost allocation = TCA (Total cost allocation)

In this scenario the system will do cost allocation for co-products in accordance with TCA (Total cost allocation) principle

Formula: AlexTire

Please note that Total cost allocation checkbox is selected for the formula to enable TCA (Total cost allocation) for co-products

Formula: AlexTire – Co-Products (Estimate cost)

Based on TCA (Total cost allocation) principle the system calculates the cost as a weighted average between the quantities that are reported as finished for product and co-products. On Estimate cost screen you can calculate Cost allocation percentages for co-products using Allocate cost percentages function.

Formula: AlexTire – Co-Products

As the result Cost allocation percentages will be calculated for co-products. In this scenario Cost allocation percentage = 0.1332%

Inventory transactions

Please note that financial cost for Co-Slag co-product inventory receipt transaction is 0.12$ which was calculated as percentage based on total production cost

Appendix B: By-products

Please see different scenarios for burden cost for by-products described below. For the sake of clarity in these scenarios only by-product (and no co-product) is the secondary outcome for production process.

Scenarios

<![if !supportLists]>1. <![endif]>Burden = None

In this scenario the system doesn’t add burden cost related to by-products to total production cost

Formula: AlexTire – Co-Products

Please note that Burden = None for By-Slag by-product. This means that the system will not add burden cost related to By-Slag by-product to total production cost

Inventory transactions

Please note that financial cost for By-Slag by-product inventory receipt transaction is 0 (Zero) and total cost of production was not increased (no burden)

<![if !supportLists]>2. <![endif]>Burden = Per (Percent)

The system allows you to add burden cost related to by-products to total production cost based on Percent, Per series and Per quantity. In this scenario the system will add burden cost related to by-products in accordance with By-product burden amount (Percent) specified manually

Formula: AlexTire – Co-Products

Please note that Burden = Percent for By-Slag by-product. This means that the system will add burden cost of By-Slag by-product as 50% percentage of total production cost into total production cost

Inventory transactions

Please note that financial cost for By-Slag by-product inventory receipt transaction is 0 (Zero) and financial cost of Car tire (AlexTire) inventory receipt transaction increased to 130.57$ because burden cost applied

When you End the batch order the burden value is calculated automatically and posted in Route card journal adding to the cost of the batch order

Production order: AlexTire – Route card journal

Route card journal header references Batch order for Car tire (AlexTire)

Route card journal lines have details of burden cost applied for Car tire (AlexTire) production

Batch order: AlexTire – Production posting

The result of burden cost applied for Car tire (AlexTire) batch order is reflected in Production posting details

Please see details of Production posting for Car tire (AlexTire) batch order in the table below

| Route consumption

Route consumption is 41.25$ based on burden applied for Car tire (AlexTire) production

*Inventory transactions

Inventory receipt transaction for Car tire (AlexTire) will be displayed on Voucher transactions screen for route consumption

*Voucher transactions

Ledger voucher provides details on which account was credited for “Production WIP issue”, which account was debited for “Production - WIP” because of burden applied

*Route transactions

Route transactions show the details of burden posting (41.25$)

|

Summary: This document describes a primer of process manufacturing approach to Car tires production in Microsoft Dynamics AX 2012. The scenario operates with single level formula with co/by-products. Batch order is a main document in process approach which controls manufacturing process and provides a context for cost accounting. In this scenario I highlighted all aspects of manufacturing process including setup, creation, estimation, scheduling, execution and costing. Most importantly I’m giving a detailed practical example of how to implement typical manufacturing scenario using process approach in Microsoft Dynamics AX 2012. This provides a foundation for comparison between traditional approach and process approach in Microsoft Dynamics AX 2012. Please review other documents in the series to compare traditional manufacturing approach with other manufacturing approaches in Microsoft Dynamics AX 2012

Version: Microsoft Dynamics AX 2012 FPK Demo VM (CEU)

Tags: Microsoft Dynamics ERP, Microsoft Dynamics AX 2012, Manufacturing, Production, Discrete Manufacturing, Traditional Approach, Process Manufacturing, Process Approach, Production Order, Batch Order, Setup, Creation, Estimation, Scheduling, Execution, Costing.

Note: This document is intended for information purposes only, presented as it is with no warranties from the author. This document may be updated with more content to better outline the concepts and describe the examples.

Excellent Sir

ReplyDeleteWhy by_product don't have financial cost amount on transaction form.

ReplyDeleteIt has physical cost amount