Microsoft Dynamics AX 2012 Cross-Functional Resource Scheduling – Part 1

Purpose: The purpose of this document is to illustrate how Resource Scheduling engine works in Microsoft Dynamics AX 2012 in cross-functional scenarios.

Challenge: Often times during large deployments of Microsoft Dynamics AX 2012 it is required to roll out multiple functional areas where Resource Scheduling is needed. Enterprises want to consistently and uniformly maintain the info about resources, their capacities and schedule their activities in relation to various tasks. For example, an employee may be involved on the project doing project-related work and at the same time the same employee may be involved on the shop floor working on production jobs, in addition it may be some future activities planned for this employee which we want to properly account for.

Solution: Microsoft Dynamics AX 2012 provides robust, highly configurable and extensible Resource Scheduling engine which satisfies needs of multiple functional areas such as Production control, Project management and accounting and Master Planning. Resource and Capacity model in Microsoft Dynamics AX 2012 spans across multiple functional areas and provides a single point of info about resources capacity and availability at any time.

Scenario

In this walkthrough I'll go over multiple functional areas such as Production control, Project management and accounting, Master Planning and Service management to illustrate how to schedule resources for various activities. I'll also touch upon graphical scheduling aspects using Gantt charts and production jobs rescheduling aspects using Production dispatch. Please note that in Part 1 I focus on Scheduling and in Part 2 I'm going to cover Execution (including Manufacturing Execution).

Below I provide an end-to-end scenario which you can replicate using standard Microsoft Dynamics AX 2012 Demo VM available on Partner Source here (requires Login): https://mbs.microsoft.com/partnersource/northamerica/sales-marketing/demo-tools/virtual-machines/AX2012DemoToolsMaterials

I'll start with creation of Worker who will be involved in various activities related to projects, production, planning and service in the organization.

Worker

Worker

As a part of preparation work I'll now create a Production unit for production-related activities

Production unit

Next I'll create a Resource group, assign newly created Production unit to it and mark Finite capacity checkbox because I want my resources capacities to be limited

Resource group

Then I'll create a Resource of type = Human Resource and assign my worker to it. Finally I can also assign this Resource to Resource group which I created earlier

Resource

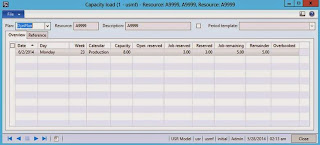

Please note that I associated my Resource with a Resource group and also specified a Calendar which defines Resource's capacity. Now by invoking "Capacity load" function I can review capacities of my resource daily

Capacity load

According to the Calendar my Resource has 8 hours of capacity daily. I can also see it visually/graphically by invoking "Graphical capacity load" function

Capacity load, graphically

By clicking Setup button I can get access to different parameters of this form

Capacity profile

Note: Checkboxes in Load section is a good indication of what is a subject for capacity planning in Microsoft Dynamics AX 2012

In addition to it I can also review existing Capacity reservations for my Resource by invoking "Capacity reservations" function. There're no capacity reservations yet because I didn't do any scheduling against this resource yet

Capacity reservations

Okay now let's review the first functional scenario related to Production control

Scenario 1: Production control

I will start by creating a new Production order

Production order

Production order

For the sake of simplicity I'll simplify Production BOM to look like below (only 1 component)

Production BOM

I'll also simplify Production route to look like below (only 1 operation)

Production route

Note: Runtime gets overridden when you change Cost group settings, so please reenter Runtime if needed

Production route - Times

Now I want this operation to be scheduled exactly against my resource. For this purpose I'll define a Resource requirement of type Resource

Production route – Resource requirement

Note: Please note that you can only define one Resource requirement of certain type per Operation because otherwise those resource requirements would contradict

On Scheduling tab you can review the details of Scheduling for this operation, no details here because we didn't schedule anything yet

Production route - Scheduling

After we defined Resource requirement for operation we can also double check it on Applicable resources form, okay, the system will only consider my Resource for this operation

Applicable resources

Now we are ready to start Production order Scheduling

First we'll do Operation scheduling which will give us Start and End dates for the operation

Operations scheduling

We also want to make sure that we do Operations scheduling with Finite capacity constraint

Operations scheduling

At this point our Production order is Scheduled (Operations scheduled) which gives us a rough picture of what will happen

Production order

On Production route Scheduling tab we'll see Start and End dates for the operation. Times 12:00am is a default times and it means blank for us

Production route - Scheduling

When doing Operations scheduling the system will not break operations into jobs that's why Jobs screen is empty now

Jobs

Because we scheduled our Production order we can now review that 1 hour of capacity has been taken away from my resource on Capacity reservations form

Capacity reservations

You can also see that this 1 hour of capacity is taken away from the specific date. This can be seen in a broader picture on Capacity load screen

Capacity load

After we did a rough scheduling we now want to do a precise scheduling and find out about exact dates and times of when this operation can be completed. For this purpose we'll do Job Scheduling now

Job scheduling

Similarly we want to make sure Finite capacity constraint is in place

Job scheduling

Now out production order is Scheduled (Job Scheduled) again

Production order

At this point we know that our operation will start at 10:00am and will end at 11:00am on a specific date

Production route – Scheduling

We can also see Jobs generated based on Operation Times. We only specified RunTime that's why the system created only one job as shown below

Jobs

Capacity reservation has been updated too, now it shows exact times

Capacity reservations

No change on Capacity load screen because the total operation time hasn't change since. But you can see explicitly what time was reserved against Jobs and what time was reserved against Operations which gives you a meaningful insight

Capacity load

If we come back to Graphical capacity load screen and select a particular date you will be able to see that total capacity is displayed in Blue and used capacity is displayed in Yellow. You can also visually assess of how much time is still available for the resource on that date

Graphical capacity load

After we Scheduled Production order we can now invoke a Gantt chart to see our scheduled production related activities on the timeline

Here's the Resource centric view of Gantt chart

Resource view

You can also switch to Order centric view of Gantt chart

Order view

On the Gantt chart you can get more info about scheduled activities by using right click, do drag-n-drop rescheduling and more. After you do manipulations on a Gantt chart you will need to click "Validate" button which would validate your changes against the scheduling data, finally to save your changes you would click "Save" button

This is a quick run through Production scheduling and now I propose to switch to Project scheduling because my Resource is also supposed to do some project related work

Scenario 2: Project management and accounting

We'll start from preparing the Project for Project scheduling

First off I'll specify Scheduling calendar on Project team and scheduling tab which is required before you begin scheduling

Project

Then I'll switch to Worker screen to do some additional Project related setup

Worker

I'll continue with Assigning workers to the Project which may be required from Validation perspective. You can assign Workers to a Project or vice versa assign Projects to Workers. Below is an example of Assign workers to Project screen which you invoke from Project screen

Assign workers

Assign workers

Then I'll open Project setup screen to specify Resource Scheduling Calendar for a Worker

Project setup

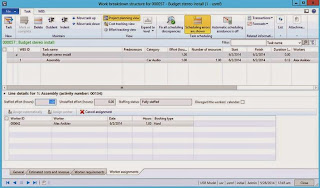

Now we are ready to define Project WBS – planned activities for the project. Here I created "Assembly" task and assigned 1 hour effort to it

WBS

Then you can select the task and try to Assign worker to the task

Infolog

Potentially you may get this message if there's nobody available for the task

Infolog

In case there're options for Worker assignment, and in our case I explicitly specified that only my Worker can work on this project, the system will present you with Worker assignment screen

Worker assignment

It is also useful to mark "Display remaining capacity" checkbox which in my case will display 8 hours of capacity for Monday for my Worker. After that you may decide to Soft book or Hard book Workers time for this task. I'll proceed with Hard booking by clicking at Hard book button and specifying number of hours I want to book (1 hour)

Hard book > Specify hours

When you finish the system will update remaining capacity for Worker for that date and you will see only 7 hours remaining

Worker assignment

Now when we come back to WBS screen we'll see Hard booking in place for "Assembly" task

WBS

This can also be seen on Project level

Project

In the example above I used WBS screen to introduce a task for the Project, however you can also use Microsoft Project integration feature to work with WBS. This is how Microsoft Project client looks like when I open Project WBS there

Microsoft Project

When you are done with manipulations in Microsoft Project client you can publish your changes back to AX. If you want to keep working on WBS screen inside of AX after you established a link between Project in AX and Microsoft Project client, you will need to use Unlink from Microsoft Project function to do so

WBS

Coming back to my scenario, after I hard-booked my Worker for 1 hour for "Assembly" task no additional capacity reservations occur at this point. This is because WBS tasks are not a subject for Resource scheduling, they just represent expected project activities

In order to reflect bookings I've done in Resources capacity reservations I'll now transfer WBS estimates to Hour forecast. From that point Project Hour forecast will become a subject for Resource Scheduling

Transfer WBS estimates to forecast

Here's my Project hour forecast which I can now Schedule as appropriate

Hour forecasts

But before I go ahead with scheduling I'll also specify Resource requirement constraint to make sure my Resource is assigned to this activity

Hour forecast – Resource requirement

At this point on Scheduling tab there's no Resource assigned to this activity

Hour forecast - Scheduling

After I defined a Resource requirement constraint I can also review a list of applicable resources

Applicable resources

And finally I can do actual Scheduling, I'll start with Operations Scheduling with Finite capacity

By the result of Operations Scheduling my Resource gets assigned to the Hour forecast record

Hour forecast - Scheduling

On Capacity load screen I can now see that only 6 hours remained, this is because the same Resource was also involved on Production job on the same date

Capacity load

On Capacity reservations screen I can explicitly see that there're 2 reservations of different types (Reference), one for Project and anothet one for Production

Capacity reservations

Next I'll Schedule Project Hour forecast using Job Scheduling

Resource scheduling – Job scheduling

This time similarly to Production Scheduling the system will provide exact Dates and Time for this activity to happen

Hour forecast - Scheduling

On Capacity load screen now we see 2 hours reserved as Job reserved

Capacity load

Capacity reservations screen also reflects the fact that both jobs are Job scheduled even though they have different types

Capacity reservations

Graphical capacity load screen now shows that more capacity has been reserved for my Resource, it is 2 hours in Yellow now

Graphical capacity load

If you try to lauch Gantt chart for that date you may see the following message

Gantt chart - Project

This is because the system is not capable of displaying Project + Production activities on the Gantt chart at the same time. That's why we'll review only Project part on Gantt chart

Gantt chart – Order view

Gantt chart – Resource view

Note: And again remember that you can create your own very personalized Gantt charts using Gantt charts form

To complete the picture let's consider a Master Planning scenario now

Scenario 3: Master Planning

Before I proceed I'll now simplify Product BOM

Product BOM

I'll do simplification to Product route too

Product route

On Product route I'll make sure I have RunTime = 1 hour and ProcessQty = 1

Product route

As I did before I'll add Resource requirement constraint in order to utilize only my Resource

Product route – Resource requirement

Now we can proceed with creation of Planned Production order

Planned production order

Planned production oder

Here's how Derived requirements form look like (ala Production BOM in Production order scenario)

Derived requirements

And this is how Route for Planned production order looks like

Route

Resource requirement has been properly propagated to Planned production order

Route – Resource requirement

We can review applicable resources as usually to make sure the system only considers my Resource

Applicable resources

Please note that after you create Planned production order it gets automatically scheduled, but I will reschedule it anyways to illustrate different Scheduling methods. I'll start with rough Operations Scheduling with Finite capacity

Operations scheduling

Operation Scheduling will provide Start and End dates for scheduled activities

Planned production order

The results of scheduling can be reviewed on Route – Scheduling tab

Route – Scheduling

No Jobs created because we used Operations Scheduling

Jobs

On Capacity load screen we can now see one more hour consumed for my Resource on the same date. Please note that this capacity reservation was done in relation to "DynPlan" Dynamic Master Plan. This means that you may have parallel capacity reservations for Planned production order in relation to different Master Plans. That's why it makes sense to specify what Master Plan is in consideration when you look at Resource capacity reservations, so you can account for "conditional" capacity reservations. Capacity reservations for real Production orders are "unconditional".

Capacity load

Now if I select "DynPlan" Dynamic Master Plan on Capacity reservations screen I'll see both "unconditional" and "conditional" (belonging to selected plan) capacity reservations. Please note that we've got one more capacity reservation with Reference = Planned order

Capacity reservations

Next I'll complete this excersice with Job scheduling with Finite Capacity

Job scheduling

Now as we are done with Job Scheduling for Planned production order we can see exact times assigned to activities

Planned production order

Route - Scheduling

This time one job will be generated for the operation in route

Jobs

On Capacity load screen we'll see 3 hours as Job Reserved now

Capacity load

List of capacity reservations will now look like this

Capacity reservations

Graphically the siutation will look like this. Now we booked 3 hours for my Resource all related to different types of activities

Graphical capacity load

Once again if you try to lauch Gantt chart for this date you may see the following message

Infolog

The reason is the same as last time, the system is not capable of showing different types of activities on Gantt chart at the same time. And now we have 3 different types of activities associated with Production order, Project and Planned production order. But I'll proceed with Gantt chart for only Planned production order

Gantt chart – Resource view

Gantt chart – Order view

By now we discussed Production order, Project and Planned production order Scheduling, but there's one more aspect regarding Production scheduling I want to add. Imagine you scheduled a number of production jobs and a rush Production order comes in which you have to deliver. In this situation you may need to reprioritize and reshuffle existing production jobs for specific resource and still keep your entire Scheduling results consistent. For this purpose you can leverage Production Dispatch function which is illustrated below

Scenario 4: Production Dispatch

You can invoke Production Dispatch form from Resource screen

Resource

This is exactly what I just did. But in fact I just see only one job belonging to Production order, so there's nothing to reshuffle

Dispatching

Here's the Production job displayed on Dispatching screen

Jobs

Jobs

In order to reshuffle jobs and reschedule them nicely I'll need to have at least 2 jobs in consideration. That's why I will come back to my Planned production order and firm it, after Planned production order turns into a real Production order this will introduce the second production job I need

Thus I will firm Planned Production order

Planned production order - Firm

Firming

Now we turned Planned production order into a real Production order. Please note that it comes in as already Scheduled (Job Scheduled). This is where we left it initially

Production order

If I now look at capacity reservations I'll see 2 of them with Reference = Production, this is exactly what I need

Capacity reservations

And then I can try doing Dispatch again. This time I will see 2 jobs on Dispatching screen which I can select and reshuffle appropriately

Dispatching

After I selected those jobs I can move them Up and Down in the Sequence to prioritize some production jobs appropriately. After I defined a desired sequence of jobs I can then define Scheduling direction for the first job and schedule all the rest of them in relation to that first job. This way I can keep my entire Scheduling results consistent and move some jobs Up in the hierarchy as necessary

Dispatching – Sequence

Dispatching - Change the sequence (Up)

Now we are ready to reshuffle jobs on Job Scheduling screen

Job scheduling

I'm still interested to do Job Scheduling with Finite Capacity

Job Scheduling (1st job)

Job Scheduling (2nd job)

As the resault my production jobs will be properly rescheduled

Result – Dispatching

Please note that Production Dispatching function is meant for Production jobs (Job Scheduling)

Now I'll come back to the feature which allows you to create your own Gantt charts to display only info that you exactly need

Gantt chart

We will start with creation of Gantt chart definition in Organization administration module

Gantt charts

I'll only be interested to work with Resources which I introduced as a part of this walkthrough. That's why on Resources tab I will specify my Resource

Gantt charts - Resources

I could also have done it by specifying my Resource group on Resource groups tab because my Resource belongs to my Resource group. You can also mix Resources and Resource groups to consider only resources you want to consider for Gantt chart

Gantt chart – Resource groups

When I launch Gant chart I'll need to specify Start date in consideration. Please note that Days horizon is taken from the definition of Gantt chart

Define dates for Gantt chart

The result will look like the following

For example, Production only

Gantt chart – Resource view

Gantt chart – Order view

Gantt charts in Microsoft Dynamics AX 2012 are highly configurable. Please review available settings below

Gantt chart setup - General

Gantt chart setup - Production

Gantt chart setup – Planned production

Gantt chart setup – Project

You can configure Gantt charts in Microsoft Dynamics AX 2012 appropriately to get the most out of them

This concludes the main scenario about Resource Scheduling in Microsoft Dynamics AX 2012, but I'd still like to discuss one more thing. Microsoft Dynamics AX 2012 provides Service management module which allows you to create, control a life cycle of Service orders and more. Each Service order may have number of activities associated with it which you may need to dispatch to service technicians. The next section will illustrate how to do manual Service Dispatch in Microsoft Dynamics AX 2012. Please note that when you dispatching Service related activities it has no impact on Resource capacity reservations because Resource Scheduling engine is not utilized in this case.

Scenario 5: Service management Dispatch

I'll start this section from some required setup. First I will define a Dispatch team

Dispatch team

Then assign my Worker to this Dispatch team

Worker

Dispatch team

I'll also need to define Activity type for my future Dispatch activity. I'll create one here

Activity types

In order to make sure that Dispatch activity gets properly generated I'll need to set up Service management parameters. In particular I'll set up Create activity for Service order to Yes, Service order activity type = Repair job and Activity generation stage = In Process

Parameters

Note: Please don't forget to set up Activity generation stage otherwise your Service Dispatch activity will not be generated

Now we can create Service order and specify Preferred technician and make sure that Default line activity type is specified

Service order

Then I will advance to the next Service stage which is In Process which should generate Service Dispatch activity for me

Service order – Service stage (Next)

Note: Please note that Next stage In Process which is set up as Activity generation stage in Service management parameters

At this point we can create Service order line and see that Service Dispatch activity gets generated

Service order

This can also seen on Service order header in Activities list

Service order - Activities

This activity is now a subject for Service Dispatch

Activity

In order to do Service Dispatch I'll open Dispatch Board for a specific date

Dispatch board

The system will now display Dispatch activities on Dispatch board

Dispatch board

I'll switch to Advanced view to see all Dispatched and Undispatched activities in lower pane. Now I can also select a particular Undispatched activities and manually dispatch it to the Worker by right clicking and pressing Dispatch button

Dispatch board

After I dispatch activity it will show up in the list of Dispatched activities so I can proceed to the next Undispatched one if any

Dispatch board

After Activity is dispatched this is also reflected on Activity screen (Dispatched = Yes)

Activity

Please note that Resource Scheduling engine is not utilized in the scenario with Service Dispatch and you do it manually on Dispatch board. That's why capacity reservations will not change after I dispatched Service activity to my Worker

Capacity reservations

Note: No impact on capacity reservations when doing Service Dispatch because Resource Scheduling engine is not utilized in this scenario

Summary: This document illustrated how Resource Scheduling engine works in Microsoft Dynamics AX 2012 in cross-functional scenario. In this walkthrough we covered Production order, Project, Planned production order scheduling, also discussed Production dispatch and personalized Gantt charts. And we finished with going deeper into Service Dispatch and explanation of how Service Dispatch is different from Resource Scheduling.

Tags: Microsoft Dynamics AX 2012, Production control, Production order, Project management and accounting, Project, Master Planning, Planned order, Production dispatch, Gantt chart, Service management, Operations Scheduling, Job Scheduling, Resources, Resource groups, Capacities, Operations, Jobs.

Note: This document is intended for information purposes only, presented as it is with no warranties from the author. This document may be updated with more content to better outline the issues and describe the solutions.

Author: Alex Anikiev, PhD, MCP