Microsoft Dynamics AX 2012 Manufacturing – Lean Ninja IoT Scenario Part 4-3: Functionality/Make to Order

Continuation from here: http://ax2012manufacturing.blogspot.com/2015/10/microsoft-dynamics-ax-2012_3.html

Addendum A: MRP

Please note that in this scenario in order to generate kanban for replenishing Near Side Line location from Warehouse bulk location based on Minimum on-hand requirement we used Kanban pegging event routine. In fact we could also use MRP to generate planned or firmed kanban for these purpose. The implication of doing this may be a delay if you run MRP infrequently, that's why for a quick turnaround it is preferred to run Kanban pegging event routine in a batch.

As a part of Addendum A I'll still showcase how MRP can be used to generate kanban for replenishing Near Side Line location from Warehouse bulk location based on Minimum on-hand requirement.

So instead of running Pegging events processing we'll run MRP this time for Wheel2 item to limit the scope of MRP execution

MRP

Infolog

Now we'll look at Net requirements for Wheel2 item. There we can see how planned kanban has been generated to cover Minimum stock requirement for Wheel2 item

Net requirements

Net requirements (Side line location BULK-003)

Net requirements (Near Side line location BULK-002)

Net requirements (Near Side line location BULK-002) – Planned kanban 1

Net requirements (Near Side line location BULK-002) – Planned kanban 2

Net requirements (Warehouse location BULK-000)

Inventory transactions in this case will look like the following

Inventory transactions

Addendum B: Transfer

It was explained at the beginning why it was decided to use Manufacturing kanban to replenish Near Side Line location from Warehouse bulk location. The main reason was a necessity to implement wave kanban picking. In fact if we would not have to deal with wave kanban picking we could have used Withdrawal kanban instead. In Addendum B I'll showcase how we could set up Withdrawal kanban rule to replenish Near Side Line location from Warehouse bulk location.

This is how we will create Kanban rule and appropriate Transfer activity for production flow

Production flow: Activity = Replenish Near Side Line <- Bulk 2 (Welcome)

Production flow: Activity = Replenish Near Side Line <- Bulk 2 (New activity)

Production flow: Activity = Replenish Near Side Line <- Bulk 2 (Create transfer activity)

Production flow: Activity = Replenish Near Side Line <- Bulk 2 (Assign transfer locations)

Production flow: Activity = Replenish Near Side Line <- Bulk 2 (Assign activity time)

Production flow: Activity = Replenish Near Side Line <- Bulk 2 (Wizard completed)

Now we'll take a look at newly created activity

Production flow: Activity = Replenish Near Side Line <- Bulk 2

Production flow: Activity = Replenish Near Side Line <- Bulk 2

Then we'll create Withdrawal kanban rule as shown below

Kanban rule

Kanban rule - Events

Kanban rule – Production flow

Now I'll introduce enough on-hand for Wheel2 item in Warehouse bulk location (BULK-001), I'm not going to use WMS processes this time that's why on-hand in Warehouse location BULK-000 won't count

Inventory journal

And then I'll execute Kanban pegging event processing routine

Pegging events processing

Infolog

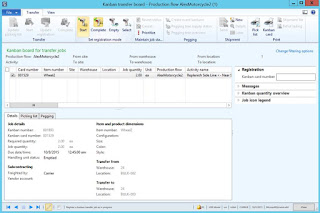

The following Withdrawal kanban has been created

Kanban

And inventory transactions at this point will look like the following

Inventory transactions (Wheel2)

This concludes the walkthrough!

Summary: In this walkthrough I illustrated how to establish an advanced Make to Order Lean Manufacturing scenario in Microsoft Dynamics AX 2012. We went through the process of setting up data, creation of initial demand, manufacturing process and Lean costing. In particular both warehouse management processes and lean manufacturing processes were used to enable this scenario. We also considered a high degree of variability, specifically, using different locations, handling different quantities and different products throughout the scenario.

Tags: Microsoft Dynamics AX 2012 R3, Lean Manufacturing, Pull, Kanbans, Kanban rules, Production flow, Warehouse Management, Hand-held devices.

Note: This document is intended for information purposes only, presented as it is with no warranties from the author. This document may be updated with more content to better outline the issues and describe the solutions.

Author: Alex Anikiev, PhD, MCP

Special thanks for collaboration in building this scenario goes to Lean Transformation Guru at MCAConnect, Phil Coy